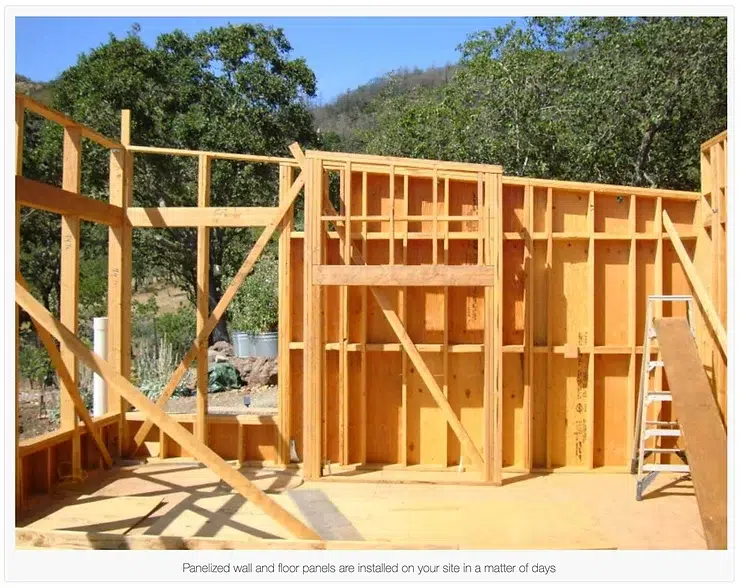

Why Panelization?

Panelization is a hybrid building method that marries the efficiency of prefab with the design flexibility and quality of a stick-built home. Our systems-based prefab construction supports a high level of design and craftsmanship while controlling costs and eliminating surprises.

- Precision: Using advanced MiTek technology, each panel is cut to measurements within 1/16th of an inch.

- Shipping: Unlike a traditional modular home, our panels are shipped flat to your building site resulting in significantly reduced shipping costs.

- Accessibility: Because our panels are shipped flat, we are able to access sites that are traditionally difficult to reach (i.e. steeply sloped, rough terrain, narrow driveways).

- Sustainability: Our modern fabrication system reduces waste by up to 50% compared to traditional building methods. All Stillwater prefab homes are highly insulated to reduce energy costs and environmental impacts.

- Time Savings: Using our highly refined three-phase process, we are able to have your home move-in ready in up to a third less time than other building methods.

- Quality: Panels are made of the highest quality Douglas Fir. They are constructed in a climate-controlled facility and are built to meet (and typically exceed) your local building code requirements.

Do you have questions regarding penalization? Please contact us at [email protected].